The Tascam DR-40 is another entry into the basic audio recorder category. It can record up to 4 tracks at once – the two internal mics and / or the two external outputs. While you can record 96khz 24bit thats probably a bit of a waste and 48K 24bit is all you’ll really need. My main interest in this unit was to add it to my sound bag when working with my mixer to add on board recording. While I do have a DR-680 that I really like, its big in comparison and I was looking for a small light solution. I normally either have the mixer or DR-680 in the bag at any given time, not both.

The DR-40 is compact enough for the job running on 3 internal AA batteries for hours. It uses standard SD cards for recording that easily go in and out of the side of the unit. It comes in fact with batteries and a 2gb card to get you recording as soon as you open the box. While 2gb is ok, I had a 8gb card I used instead. I formatted the card in the recorder before using it for the first time as the DR-40 does want to have its own folder. It records standard WAV, BWAV and MP3 files. The DR-40 will function as a USB SD card reader so you can directly access the SD card and dump the sound files onto your mac or pc.

Out of the box you’ll note the 2 built-in mics have wire metal bumper guards. With the mics facing in they will do the job as I carried this unit around for a couple of days in my pocket and all was well.

There are several side switches and buttons on the front. If you have worked with other Tascam products the menus will be familiar. They are simple and easy to figure out without reading the manual for the most part. Even just playing around with the unit for a few minutes I ran thru all the options and pretty much figured out what I needed to get the unit setup the way I wanted. The actual LCD display itself is reasonably contrasty and has a backlight with programable stay on time. Also of note is that the REC button has a nice plastic ring around it lit by a LED that makes it easy to see you are ready to record or all ready rolling. Getting into record is basically instant and there is a pre-record feature if you need or want it.

The manual is available here http://tascam.com/content/downloads/products/706/e_dr-40_om_va.pdf and I’d suggest taking a few minutes to go through it.

Phantom Power : Yes this unit has phantom power which is selectable for either 48V or 24V. When you turn phantom power on via the side switch the unit will prompt you on the front display to enable it. This is both a safety precaution and to prevent higher power consumption on the unit by accident. Running phantom power tends to use up a lot of battery power. This is true on ANY device that must convert 4-12V up to 48V, not just the Tascam.

The HOLD Switch : Located on the side of the unit is a hold switch. Its a good idea when you are in record, moving around and want to be sure you stay in record. The problem is if you move the switch, by accident of course, into the hold position with the power off. The unit will not come on if the hold switch is on. It will act like its dead or your batteries are. It took me several minutes to catch this one and get the DR-40 to turn on after changing the batteries twice. I suppose one might be able to argue this feature could save an accidental power on and your batteries.

I put a Schoeps CMC-64 into the inputs direct using 48V phantom power. It worked, it sounded pretty good. You could record dialog and be happy for a lot of work. I’d best describe it as having more bottom end and less high end. Less detail in comparison to feeding it with my mixer.

The preamps have a very low noise floor and the mic itself is pretty quite. So if your main criteria is noise levels, these preamps pass with flying colors.

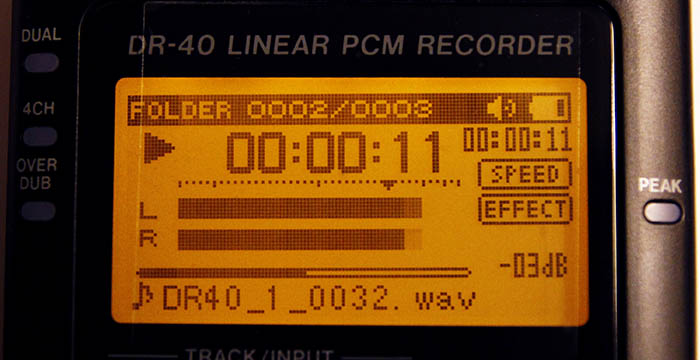

So note this : I screwed up these tests a bit. I recorded low levels because the meters in the unit ( see below ) are really kind of deceptive. Literally 80% of the meters are dedicated to what looks like the area below -18db. The last 20% is the range you really care about, the range of -18db to 0db. What looked like good healthy levels was in fact recorded by me low. Live and burn sometimes, that’s why you do tests ! That said, my error wasn’t the worst. In fact I’d say in all fairness it represents the sort of error I think a lot of people could of made using the unit for the first time. Know your gear, right ?

Putting my mess up aside, boosting the low recording levels with 18-24db of gain was still very clean compared to some other recorders I’ve used. If I had to test how quiet the preamps really are, this was a great test… I just hadn’t intended to do . Please keep this in mind when listening to the recording samples.

In comparison, using my FP33 to feed line level into the DR-40 had a more accurate sound. It had more detail in the upper end. I’m pretty sure I had the low cuts on the mixer turned on so I probably biased the recording samples a bit in them having less bottom end.

Line level sounded cleaner which is almost to be expected. My mixer has transformer isolated inputs and outputs along with a lot of head room if properly powered. So using this unit with an external mixer or pre map and feeding it line level is probably the best thing to do for best sound quality. If you are using this for recoding podcasts or news a mic on the direct input will be fine. I”m being critically picky here and in reality most folks will probably be happy with the built in pre maps for everyday recording.

The built in mics are also ok. They seem to have a lot of gain which makes them seem more sensitive than I think they really are. The built in mics sound decent. They are good enough for quick ambient recording or typical news gathering, especially if kept close enough. Of course keeping a mic close enough is important no matter what mic you have. Good mic placement is 50% of the game at least !

There are furry wind covers you get get if you want to use the DR-40 outside. Tascam does not provide any basic foam windscreen though I’m sure some foam is inside the head of each mic. If wind rumble is a problem you can engage the low cut filter with 3 different cut in points as a starting point.

With the 2 built in mics you can record with them facing each other at 90 degs or flip them to face out. The unit will detect this and ask you to change from XY to AB recording modes. The DR-40 also supports MS recording and playback. I could easily picture facing them outwards for hand held interview recording.

The one down side is that the built in mics will pick up handing noise. So if you hand hold the unit don’t be rubbing your fingers on it or otherwise messing with it. Perhaps a pair of thin gloves might help if you really have to. I did use the unit a couple of times to get some ambient material with out a problem.

The DR-40 can record in a variety of modes including : X/Y or A/B stereo, MS stereo, Ch3/4 dual (linked), CH3/4 separate, any combination of 1/2 internal mics and or 3/4 external inputs, and can even record in a basic overdub mode playing 2 channels while recording. You can record 44.1, 48 and 96khz in 16 or 24 bits to various file formats.

The DR-40 also has a built in safety recording feature. You can record from any input pair and then record 2 more channels from the same source with some level of input reduction. This is the sort of split level records I’ll manually do sometimes when things are very unpredictable and you expect you may have hot levels you aren’t ready for. Safety is good !

Another very cool feature is the ability to add delay in ms to the external inputs. This is to compensate for delay when using external mics ( or board feed ) far away in comparison the internal mics so sound is in sync.

Here is a sample of the MP3 192kbits recording from the unit. I’m not thrilled with compression quality at all. Also consider I did boost the levels up which is aggravating, but if you did this on your job – MP3 recording format and levels a bit low you may not be happy with this.

There several compression / limiting modes on the inputs. The manual is really a bit fuzzy on these, but they sound like none, hard peak limiting, auto levels and “limiting” thats more like soft compression. I didn’t have a lot of time to mess with these so you’ll want to try them on your own. I went with the hard peak limiting as I was usually using a mixer in front of the DR-40 and letting its limiters do the real work when needed.

There is a peak LED indicator on the front of the unit which is a nice help. As long as you don’t see it more than flash once in a while you should be good.

Every recorder seems to be a bit different. When working with my FP33 I set tone to +4db analog and then set the DR-40 to what I thought was -18db. This gives me about 14db of headroom before the FP33 limiters kick in and a couple more db before hitting digital 0. This seems to get reasonably good levels for me. The DR-40 seems to have a bit more gain on the inputs at line level as I set its internal input levels all the way down. Perhaps its set up for -20db consumer line level, or the Tascam engineers found that people tend to record levels that are a bit too low ( like I did the first time around ) and always want more gain. I didn’t have that problem with my mixer feeding the unit line level. Given how clean the preamps are this is a reasonable plan to give the user more gain when they could use it.

The meters on the DR-40 seemed pretty responsive and well tuned. Interesting side note : buried in a menu there is a tuner function in the DR-40 !

What was strange though was that the actual recording levels of the 48K 16bit wav files seem to be a lot lower than what the meters where telling me. This was true in both direct feed and mixer feed. I found myself applying 18-24db of gain in premiere pro to the clips to get them into the -18db to -12db range for normal dialog and what I thought I had been recording.

As I noted, this was my mistake by misreading the meters. Dear Tascam, please change the meter markings. Make the left 30% -128db to about -24db and use the rest of the meter space for -24db to 0. That would be a lot more useful !

When I did bring the levels up they where clean thanks in part to Premiere Pro’s high quality audio handling. Usable for most work but I should of gotten better levels in the files. Next time !

The DR-40 pretty much does everything you’d want – playback 2 or 4 mix down channels with mix level and pan, M/S decode, delay effects and even variable speed playback. The only down side ? the only output is the 3.5mm headphone jack. There is a small speaker on the back of the unit for quick checks though.

The unit runs for several hours on 3 internal AA batteries. I never managed to drain my rechargeables during testing of several hours on and off. I did watch the battery meter and it seemed accurate so I changed out on one bar rather than taking it all the way down. Tascam sells an external battery pack if you need extended recording time.

As for external power connector, there is none. OK, not the usual coaxial power connector just about everything has including other small Tascam recorders. Instead the choice was to use the USB port. I think this is a poor choice on every level. While you can power it from your laptop, or use a 12V->5V USB power adapter or wall power to USB adapter its far from being the ideal power connector. I’d tried it and it does work, but it won’t charge the internal batteries if you are using recharables and you should be. I’d recommend finding a right angle mini USB cable if you are regularly going to power this unit externally.

If you shoot dslr’s that’s about a 12 minute take per roll. Sync in my tests at 70deg F was 3500 samples or so off. At 24 fps its 2000 samples per frame or 2002.02 samples @ 23.976 but I like easy math. My measured distance was 3571 samples or nearly 2 frames difference at 12 minutes. Bummer because thats a noticeable sync difference. On the other hand, what do you expect for $150 or so? My DR-680 which costs 5X more does hold sync out to 12 minutes with a drift of about a 1/2 frame. What can I say, you get what you pay for ! Just be glad you’re not schlepping a Nagra around with its 10 D cells. So the bottom line is this recorder won’t hold usable sync for more than about 6 minutes at 24fps. At 30fps this would be 20% shorter before hitting 1 frames.

You could use this for sync sound, but you would be cutting your clip every 5 to 6 minus to slip it forwards a frame and then patch the gap. While this is possible to deal with it would not be my personal choice. Its also possible Plural Eyes can deal with the sync slippage too but I’m not sure this. If it can, or FCP X can the DR-40 may be very workable and affordable for you.

Its a great little recorder thats very affordable. Its perfect for simple recording work like taking a board feed of your band or news gathering. Its small size lets it fit in your pocket. Where the unit falls down is for sync sound over a few minutes. Its possible that with some variance in manufacturing you might get a unit that holds sync tighter or not. I don’t know. Either way the Tascam DR-40 should meet a lot of people’s needs for a small high quality inexpensive audio recorder.

Sennheiser HD280 Headphones Review

Headphones, especially ones for field production really aren’t glamor items the way high end mics are. In fact its one place I see people often going with whatever is cheapest rather than what is good. Good headphones are very basic and essential tool for monitoring your recording where it counts most – at the initial recording.

Perhaps the most common headphones I see out there are the Sony 7506’s folding headphones. They are certainly very common for good reason: decent sound, reasonable price, they fold up small and the other guys and gals all seem to be using them. They are something of a standard. However I think the “everybody uses them” think more than the rest is why they are so common. Personally having used them, I can’t say I’m thrilled with them. Why ? well for starters they are always falling off your head. That one thing alone drives me crazy because try booming on the run and all of a sudden your ‘phones are hanging over your shoulder in the middle of a shot. Then there is the fact they have pretty poor isolation which means cranking the volume up. This is very bad for your ears, and when working close to your subject there can be bleed or feedback.

Enter the Sennheiser HD 280’s for about the same price, give or take literally a couple dollars.

What I Like About Them

They Stay On Your Head. Go ahead, run with them on and they stay put until you take them off. Look up, down, around and they are still on. If you wear a hat with a brim, they’ll also still stay on. This is a huge advantage over many other sets of ‘phones in the market. I’ve even split worn them. That means putting just one side on your ear, the other on the side of your head. This way you can also slip on a set of intercoms too at the same time. This is very valuable when doing live TV shots in the field and you need to hear the truck, the director and your own sound all at once.

The other major advantage of these headphones is their isolation The HD 280’s are a closed style design. They offer 32db of isolation blocking out external sound. This lets you monitor with lower levels which is better for your ears. It also helps a lot in deciding if background noise is really intruding too much into your good sound or not. Lower monitoring levels is a very good thing that you should not underestimate, especially if you do sound as a part of your income.

Sound Quality

The overall sound quality is very good with specs of 8hz-25khz, although no graph is supplied. However, thats still way more than good enough for normal dialog and music recording. They tend to be reasonably neutral sounding with minimal sound coloring. This is good because you want headphones that tell you the truth about what you are getting.

Real World Use

In everyday use, I find they are very honest about what I am getting. They are detailed and don’t color the sound in any significant way. This means I’ll usually hear even really small stuff in them that you’ll not normally notice in the edit room even with decent speakers. Its always better to hear everything and be able to decide if it matters rather than not. You eventually learn to know what matters and what doesn’t. The improved isolation is a part of this experience. By reducing external noise you get a much better sense about what you are getting without having to over crank the volume to hear that. Saving your ears is a big deal, especially if audio is a part of your normal income making.

Durability

I have one pair that lives in my audio bag full time. They store into my Petrol Pegz-1’s front compartment and then route to either my FP33 mixer or DR-680 recorder. I swap out the mixer or recorder depending on the job. I’ve been using one pair now for several years. They have worked literally in falling snow, rain and hot summer sun without a problem. Thats what you expect. Even with several years of use, they have very minimal signs of wear. UPDATE : many years later and they are still holding up despite harsh conditions and weather.

If you do managed to shred up the ear pads, they are replaceable.

The HD 280’s have a 1/8″ ( 3.5mm ) jack as its native connector. Included in the box is a screw on adapter to get you to 1/4″ if you need it. This is the same 1/4″ screw on adapter that is used on Sony’s. If I have any complaint, its going to be that the connector is a straight connection rather than a 90 degree one. I know most headphones come this way and its not great because it makes them much more easy to break. For these headphones and just about any I highly recommend putting a 90 deg adapter on them. There are even 1/8 to 1/4″ adapters if you look around a bit. Generally speaking if you find them online they are pretty cheap so getting 2 or 3 is often a good idea to have a spare or for your other headphones you may have around.

Recommendation

I’m doing audio for national networks ( live feeds and ENG ) and there are no excuses or second chances. You get it right or you don’t work again for them. In this kind of high stakes environment you tools have to work correctly every time. A quality set of headphones has to be a sound person’s most important tool after their mic and mixer. For once its nice not to go broke for quality gear that performs. Its certainly easy to spend a lot more for pro level headphones, but the HD 280’s are real performers that work day in day out and won’t break the bank. Its nice to have reliable quality gear at a very reasonable price.

Kenko 1.4X Tele Extender / Converter Video Review For EF Mount

Sometimes you need a little more reach with a lens. I’ve even used this with a 50mm prime to get 75mm. This adapter unlike Canon’s will work with pretty much any lens, not just long tele glass. It also doesn’t suffer from a rear element that protrudes past the rear of the lens mount. Optically its on par with any of the big name lens extenders.

Tamron 17-50 2.8 Lens Review

Its funny how I never got around to talking about this lens – the Tamron 17-50 2.8. It was the first lens I got along with the 70-200 2.8 and has also been one of my more popular videos on youtube.

Can a $25 or $100 Lens Make A Nice Image ?

Yes ! I shot this with a [EDIT original post Vivitar 24mm F2.0 lens that I got for $25] Jupiter 9 I got for around $100. Looking on eBay I see its going for more like $250+ referring to the Vivitar 24. I got a bargain for once, and a really nice lens ! Its entirely possible you may come into this lens nearly as cheap. Before you plunge big dollars into something with a C name on it, consider what else is out there. Many a vintage lens will still make a wonderful image. This was shot in a little inlet on Lake Winnebago, WI.

The next image was shot with a Vivitar / Tokina 400mm 5.6. Maybe not quite as sharp as I’d like, but I was hand holding it at 125th shutter or so and high ISO. Even still it held nice contrast on severe back lighting. Ok, truth be told I did pay around $100 for the 400mm, but even still a bargain compared to alternatives.

The point is I got into dslr imaging because I was intrigued with making high quality video ( and some stills ) for cheap. I’m thrilled I DIDN’T spend thousands on gLamour gLass and found some great lenses that work just fine. Ok, Ok, yes, yes, that gLamour Luxury glass will do better, no doubt but I’m just not making images were clients will ever know, care or see the difference. Its nice not to be gear poor for a change ! Seriously, quit pixel peeping and make some great images.

Vivitar 24 F2.0